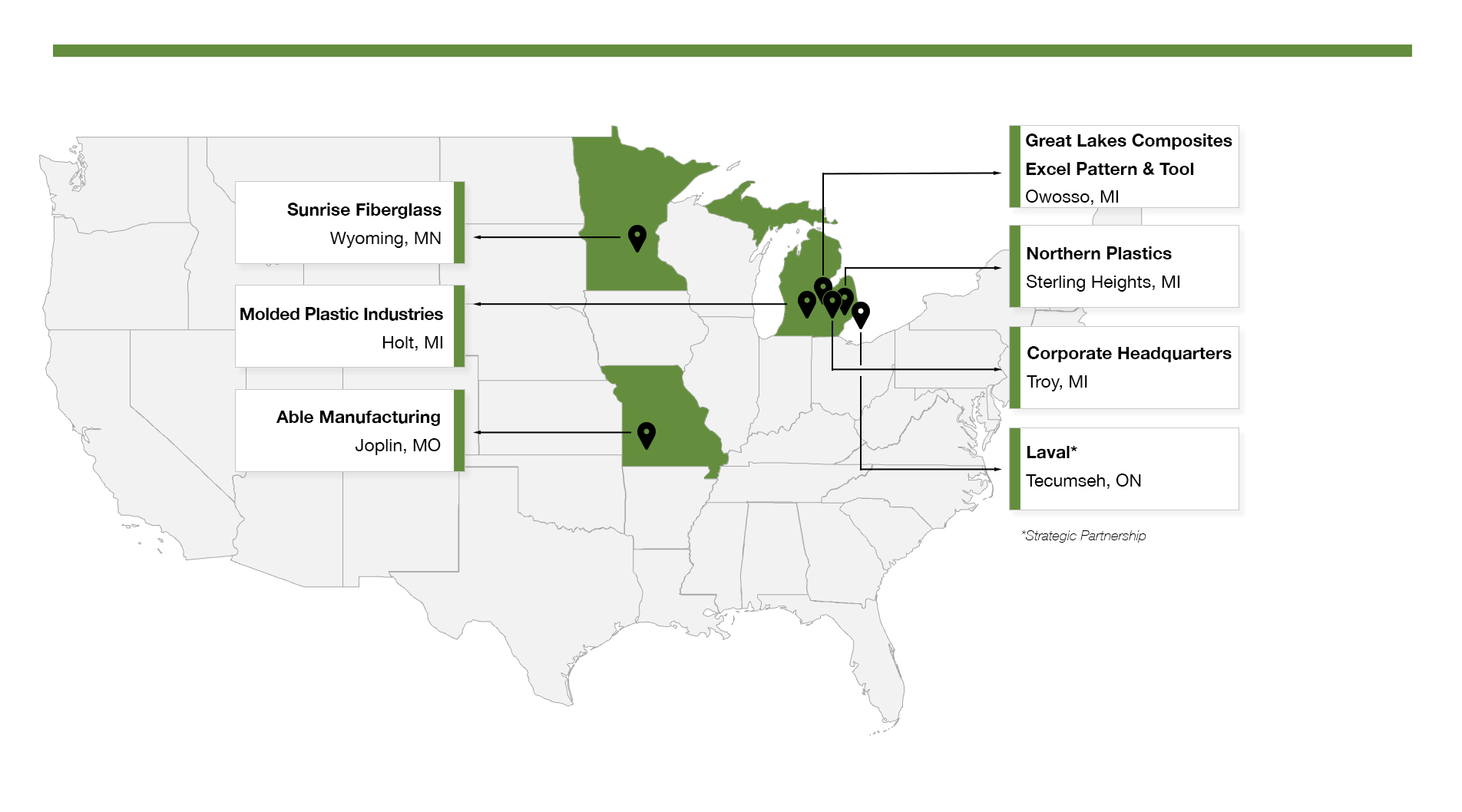

National Composites

Engineering that solves problems

Able Manufacturing

Joplin, MO

Great Lakes Composites

Owosso, MI

Molded Plastics Industries

Holt, MI

Excel Pattern and Tool

Owosso, MI

Sunrise Fiberglass

Wyoming, MN

Laval

Ontario, Canada

Northern Plastics

Sterling Heights, Michigan

Small plant focus, Big company resources

National Composites, is a multi-plant OEM supplier of custom molded FRP, Thermoformed plastic, and full metal cab fabrications and assembly. National Composites utilizes multiple FRP molding methods including open mold, LRTM, RTM, and compression molding. National Composites offers the convenience, engagement, and focus of small production facilities with the resources of a large organization. We can assist on metal and composite product design (as needed), pattern build in house, R&D and prototyping, tool and fixture build in house, volume and product diversity with our multitude of molding capabilities, and class A paint capabilities. Additionally, NC is a full assembly group dedicated to value-add component installation and assembly.

National Composites operates over 600,000 square feet of production space that spans six plants and three states. Our production facilities serve as individual entities but with the shared resources of business development, design, engineering, finance, and executive management. This approach ensures that our customers have advanced support from design, prototype, and material selection stage to full scale production. Whether the initiative is a one part production or tens of thousands, NC possesses the diverse facilities and processes to handle any size program.

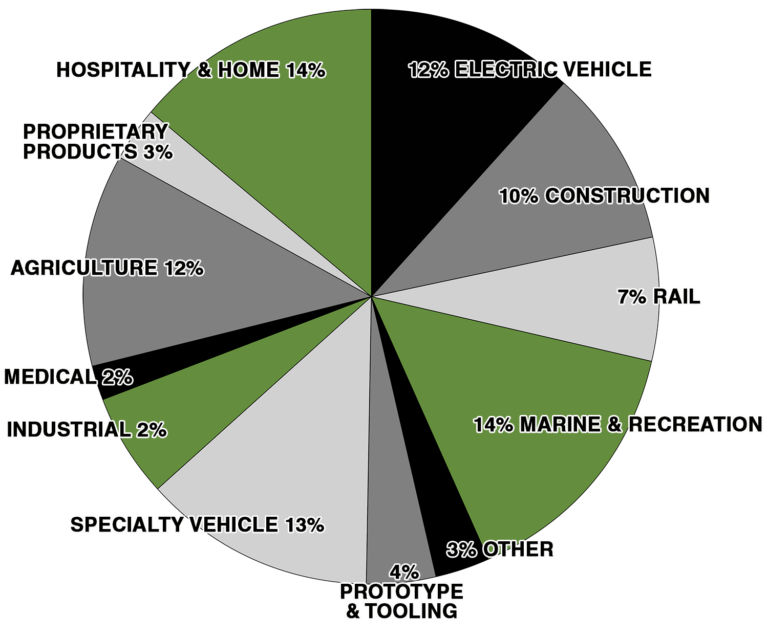

National Composite’s unique approach to the market allows us to be versatile and agile in the markets that we serve. The diverse and ever expanding needs of these iFFndustries requires that NC continues to grow and evolve withFF the world around us. At National Composites we strive to deliver more than just quality products, we are dedicated to being a true partner with people you can rely on.

Locations

National Composites Specializes In

- Fiberglass Reinforced Thermoform Plastics

- Prototyping

- Tooling

- Open molding

- LRTM

- RTM

- CCBM (bag molding)

- Compression Molding

- Vacuum / Thermoforming

- Metal Fabrication

- Operator Cab Fabrication

- Class A Paint

Trusted By

National Composites works with North American companies of all sizes. The brands below are just a small sample of the companies that place their trust in us. If your company is seeking a partner for your next project, contact us at sales@nationalcomposites.com.

Heavy Equipment

Our team has decades of experience in the heavy equipment market producing interior and exterior panels. Utilizing both open and closed molding capabilities we are building parts for some of the leaders in the heavy equipment market. We are currently building parts for cranes, skid-steers, paving equipment, mining equipment, trains, and more. Our engineering department has a deep understanding of the unique structural requirements needed for the heavy equipment industry.

Heavy Equipment production takes place at our Wyoming MN plant, Sunrise Fiberglass.

Hospitality

National Composites is currently producing a wide array of products including, walk-in bathtubs, restaurant booths, residential/office furniture, door skins, and more. Our team has years of experience in the market with a deep understanding of the cosmetic and structural needs.

Hospitality production is located in one of our Owosso Michigan plants, Great Lakes Composite.

Other Markets

National Composites is focused on providing total program management solutions as we grow and expand into other markets. The leaders of our multiple production plants have decades of experience in composites serving multiple different markets. Some of the other markets currently being served include.

- Agriculture

- Transportation

- Tanks

- Corrosion Protection

- Infrastructure

- Water Treatment

- Mass Transit

For more information on the various markets we serve please contact our sales team located in our Troy Michigan headquarters.

Prototype, Pattern, and Tooling

Our tooling division’s key members have over 100 years of combined experience. Some of the world’s leading companies’ ideas are brought to life through our tooling plant. We are working with a multitude of different industry leaders as well as other plastic FRP and composite suppliers around the country. Our capabilities include prototype and production gauges, fixtures, pattern cutting, and tooling.

Our tooling production takes place at our second Owosso location, Excel Pattern and Tool.

Medical

Our medical division is producing parts for some of the household names in the medical industry. Typically using the closed molding process, we are producing a variety of parts for the medical industry, including a variety of exterior panels and housings, as well as medical table components.

Medical production takes place in our Holt Michigan plant, MPI.

Electric and Specialty Vehicle

Since 1974 we have been working with some of the top innovators in the market. We have a deep understanding of the market’s quality and tolerance expectations. Typically using closed molding methods and thermoforming, we have experience creating a multitude of vehicle parts. For many of our customers we provide “plug and play” assemblies, installing electrical components, lighting, heat shielding, and sound suppression components. We are currently serving a variety of customers within the market supplying both interior and exterior components. From fire truck and bus to military and automotive, we have the capabilities to meet our customs needs.

Automotive and Specialty Vehicle production takes place in our Holt Michigan plant, MPI.

Marine and Recreation

National Composites marine and recreation division has been supplying the nation’s top pontoon and boat manufacturers for years. Utilizing open and closed molding methods we produce helm stands, center consoles, seat bases, table/bar tops, doors, and more. With a deep understanding of the high part quality expectations and the constantly adapting colors and styles, our team are marine experts, specializing in the latest trends of poly flake and metallics gel coats, as well as complex multi gated molds. Our marine division also has a dedicated secondary component assembly group very experienced in the assembly of helm stands and center consoles.

Marine and Recreation production is located in one of our Owosso Michigan plants, Great Lakes Composites.

Latest News

National Composites Expands into Thermoplastics with Acquisition of Northern Plastics

National Composites Announces Strategic Partnership with Laval

Get Started

Get started on your next project. Send us a message with our online form.

Request A Quote

- Experience

- Craftsmanship

- Dedication